Material Testing

KitPackers sets itself apart from other contract packaging companies thanks to our shared facilities and management with ResinLab, providing us with the ability to perform extensive material testing. Our technical staff includes chemists and chemical engineers who are experienced in providing material testing and have the latest analytical equipment to characterize or troubleshoot material issues.

We can provide the following tests in-house and will contract out any required tests that we can’t provide to another trusted lab:

Rheological Properties

- Viscosity

- Gel Time/Pot Life

- Sag & Flow Rates

- Thixotropic Index

Thermal Properties

- Coefficient of Thermal Expansion (CTE)

- Glass Transition Temperature (Tg)

- Specific Heat

- Degree of Cure

- Thermal Diffusivity

- Conductivity (K)

Flammability Properties

UL 94 Testing both vertical (UL94V) and horizontal (UL94HB) using both 3 mm and 6 mm specimens.

Chemical Characterization

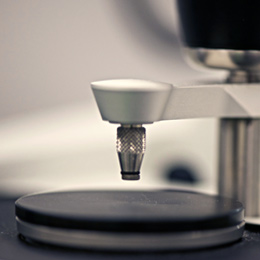

Determine chemical composition for QA comparison through the Fourier Transform Infrared Spectrometer (FTIR) including impurity analysis.

Mechanical Properties

- Adhesive strength via lap shears or peel tests

- Tensile & yield strengths plus moduli

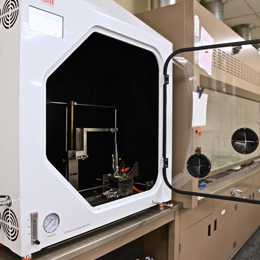

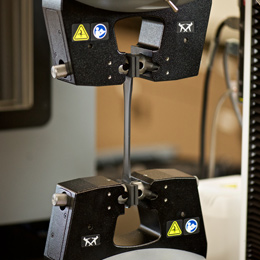

- Compressive, flexural, and tear strengths through the Instron Universal Tester with an environmental chamber

Electrical Properties

- Electrical Conductivity & Resistivity

- Volume & Surface Resistivity

- Dielectric Strength

- Dielectric Constant